How To: Get Rid of Wheelbite

Wheelbite is a major problem in any discipline of skateboarding or longboarding. What is wheelbite you might ask? It is exactly what it sounds like! When your wheels are too big, your board is without wheelwell cutouts, you just run really loose trucks, or all of the above, you have a high likelihood of your wheels to rubbing against your deck. This can cause an abrupt and unwanted stop to your ride. This is most commonly found with those who ride topmount boards, but it can happen with any other mounting style as well. For example, drop-through boards like the Hi5ber Makako or the Pantheon Ember could get wheelbite if you have trucks that move the wheelbase inward. Nonetheless, there are four ways to remedy wheelbite. Here they are in no specific order

1. Risers

Pro's: No more wheelbite, more room for turning, shock absorption, inexpensive

Neutral: More grip (good for downhill, bad for freeride)

Con's: More ride height, need longer hardware, takes more time to switch trucks

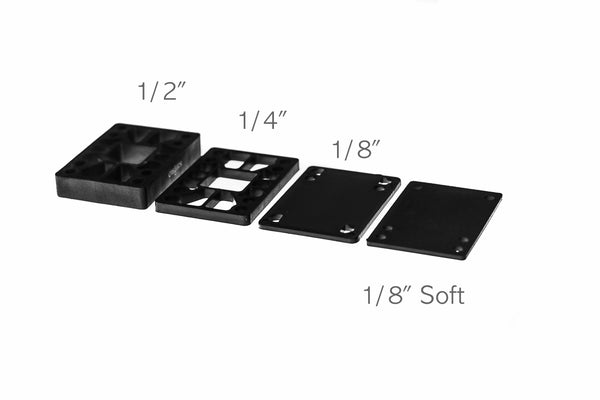

Adding risers to your setup is the most common and straight-forward method to eliminating wheelbite. This may come in the form of a shock pad, an 1/8", 1/4", or 1/2" riser.

Typically, the less ride height the better (unless your preference is higher off the ground). Therefore, you can combine many of the other methods of stopping wheelbite (like changing your bushings) with a lesser riser option to combat the problem without changing your height too drastically. Along similar lines, angled risers will also do the trick, and change the feeling of your setup. Using wedging and dewedging takes experience and knowledge, so feel free to consult us or other experts before you make alterations. If you're getting risers, make sure you have long enough hardware and the proper skate tool to accommodate.

2. Bushings/Tightening Trucks

Pro's: No more wheelbite, inexpensive, easy to change

Neutral: Changes your truck feel (good if you didn't like it, bad if you liked it)

Con's: Requires intuition or research

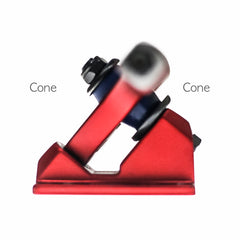

Swapping your bushing setup can easily get rid of any wheelbite issues as well! This is accomplished by either upping the durometer, changing to bushings with more urethane (stepped cones/eliminators), or a combination of the two. Any of these are feasible wheelbite solutions because they restrict your immediate turning and generally change how your trucks operate. Changing the shape of your bushings will make the most impact.

So, if you're riding a cone/cone setup, swap to a barrel/cone

barrel/cone--->barrel/barrel

barrel/barrel---> stepped cone/barrel

stepped cone/barrel ---> eliminator/barrel

eliminator/barrel--->stepped cone/stepped cone

We find that stepped cone/freeride bushings from Venom help combat wheelbite the best of all due to their height, shape, and width. They have the same height as a barrel, yet are much wider with a shape that lends to much more gradual turns. Bushing setups are a tricky thing, so never hesitate to email or give us a call!

3. Smaller Wheels

Pro's: No more wheelbite, easy to change, often easier to slide

Neutral: Different feels

Con's: Slower roll speed, more expensive

Attack the wheelbite problem directly at its source, those damned wheels! If you're running 80mm Orangatang Kegels on a Madrid Dominant without a riser, you're going to have a bad time. Downsize to some 69mm Powell Snakes, or if you're freeriding, get some 60mm Free Ranges. In general, the only time smaller wheels would be a bummer is for downhill roll speed, or for wheels that die quickly and you would want to cherish.

4. Sand in Wheel Wells

Pro's: No more wheelbite, inexpensive

Neutral: Takes time and effort

Con's: Potential threat to structural integrity, takes the most time/resources/experience

Out of all the ways to get rid of wheelbite, sanding in your own wheel wells will take the most time and knowledge, as well as be the most risky. Obviously, this is relating to the wooden boards, and is not applicable for fiberglass/carbon fiber/composite boards. There are many "ghetto", and "non-ghetto" methods to sand wheel wells. If you are without proper tools, get some coarse grip tape like Vicious and go to town! If you're not "ghetto", use a sander or an angle grinder if you know how!

BAMMMMMMMMMMMMMMMMMMMMMMMMMMMMM WHEELBITE FIXED

If it is not fixed after any of these four remedies, call us at 206.372.5268 and we'll get to the bottom of this!

Return to the FAQs section